1.General Description

The 4660 VW Settlement System is designed to measure the differential settlement between two points. A reservoir is located at a stable reference point and is connected to a sensor located at the settlement point by two liquid filled tubes. The sensor senses the pressure of liquid within the tube. This provides a measure of the height of the liquid column, which in turn gives a measurement of the elevation difference between the reservoir and the sensor.

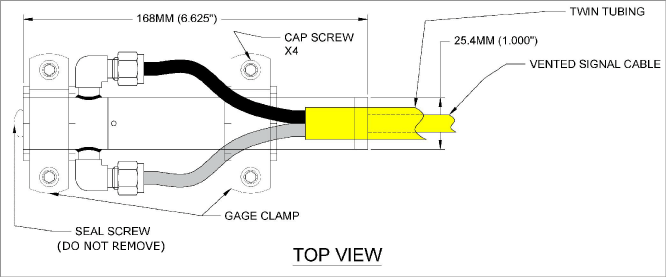

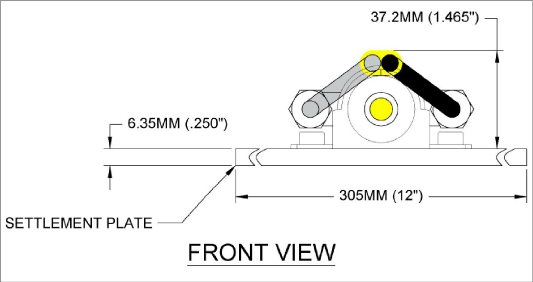

The sensor contains a thermistor for measurement of temperature, as wells as gas discharge tubes for protection against lightning damage. The cable contains a vent tube that connects the air inside the sensor to the space above the reservoir. This ensures that the sensor readings are unaffected by any changes in barometric pressure. A desiccant chamber located at the reservoir end of the vent line prevents moisture from migrating into the line. The figures below show the details of the sensor assembly with the vented signal cable attached. Note that the seal screw shown in Figure 1 should not be removed.

Figure 1: Sensor Detail Top View

Figure 2: Sensor Detail Front View

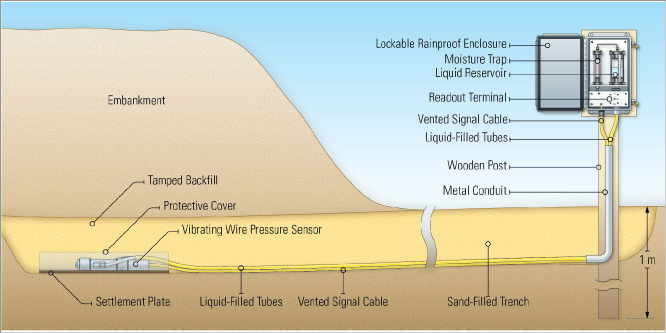

Figure 3 below shows a typical installation used to measure the settlement inside an embankment. The sensor is read by means of an electrical cable extending to the readout location. Readout may be by any GK-404, GK-405, or CR-6 datalogger. The sensor contains a thermistor for measurement of temperature and has gas discharge tubes for protection against lightning damage. The cable also contains a vent tube that connects the air inside the sensor to the space above the reservoir. This ensures that the sensor readings are unaffected by any changes in barometric pressure. A desiccant chamber located at the reservoir end of the vent line prevents moisture from migrating into the line. Single and two-channel reservoirs (Models 4650-4A and 4650-4B) have a thermistor mounted to the back of the PCB inside the reservoir to record temperature changes at the readout terminal.

Figure 3: Typical Installation of Vibrating Wire Settlement System

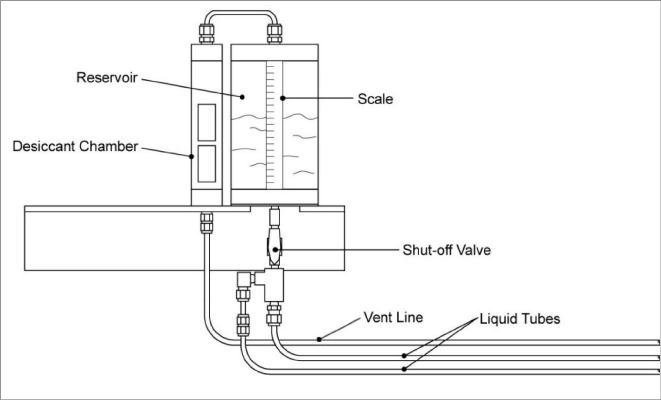

The figure below shows details of a typical reservoir system. Two liquid filled tubes are provided for each sensor and more than one sensor can be connected to a single reservoir. The use of two liquid filled tubes permits the tubing to be flushed periodically to remove any accumulation of air bubbles. With this type of liquid settlement sensor, it is vital that there be no air bubbles in the liquid line. The liquid used is typically a de-aired antifreeze mixture, which resists the growth of algae and is not susceptible to freezing.

Figure 4: Reservoir Details