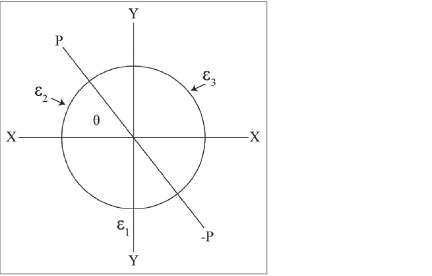

Appendix G.Calculations from Three Strain Gauges, at 60 Degrees, on a Circular Pipe

21:

Figure 21: Three Strain Gauges Mounted on a Circular Pipe Diagram

A = (ε1 + ε2 + ε3) / 3

Equation 17: Average Axial Strain

(Y) = ±[((ε1 + ε2 + ε3) / 3) – ε1]

Equation 18: Maximum Bending Strain Around the YY Axis

(X) = ±[(ε2 – ε3) / 1.732]

Equation 19: Maximum Bending Strain Around the XX Axis

P = ±[Xcosθ + Ysinθ] + A and tanθ = Y/X

Equation 20: Maximum Strain

Let ε1 = 20, ε2 = 192 and ε3 = 88 (all tensile strains)

Average Axial Strain, A = (20 + 192 + 88) / 3 = 100 microstrains, tension

X = ±(104 / 1.732) = ±60

Y = ±(300 / 3 – 20) = ±80

tanθ = 80 / 60 = 1.333 and θ = 53 degrees from the X axis

P = ±[60 x 0.6 + 80 x 0.8] + 100 = 200 microstrains, tensile, 0 microstrain minimum