Loading... Please wait...

Loading... Please wait...-

Products

- Piezometers

- Inclinometers

- Strain Gauges

- Data Loggers

- Displacement Transducers

- Extensometers

- Settlement Sensors

- Pressure Cells

- Load Cells

- Tiltmeters · Pendulums

- Readouts

- Visualization Software

- Stressmeters

- Distributed Fiber Optic Sensors

- Temperature

- Instrumentation Cables

- DeAerators

- Vibration Monitoring

- Custom Instrumentation

- Discontinued

- Support

- Training

- Contact Us

- News

- Company

- Projects

- Resources

- Videos

- Links

Resources

Session 01

A Geotechnical Engineer’s Guide to MEMS Accelerometer Specifications (Part 1 • Terminology)

Posted April 28, 2021

As a geotechnical engineer you may ask yourself, why do I care about Micro-Electro-Mechanical Systems (MEMS) accelerometers? The term MEMS accelerometer is somewhat misleading in the sense that many geotechnical instruments use MEMS sensors to measure static tilt, not dynamic acceleration. MEMS come in single axis, bi-axial, and more recently tri-axial chips, and depending on the use case each can be appropriate.

When looking at tilt measuring instruments, geotechnical engineers are typically concerned with one thing, “how accurate are the readings.” The term accuracy is often (and incorrectly) used to refer to the smallest change in angle that an instrument can detect. When studying specification sheets for tilt sensors you may find the following terms:

- Accuracy

- Precision

- Resolution

- Sensitivity

- Non-linearity

- Temperature Dependent Uncertainty

- Repeatability

- Noise

As there is no industry wide standard with respect to specifications for geotechnical instrumentation using MEMS sensors, you may find yourself overwhelmed and quickly confused when comparing the specified performance of various products. To further complicate matters, there typically is no differentiation between sensor specification values (i.e. chip level specifications derived in a controlled environment) and system values (i.e. the geotechnical instrument, comprising interfacing electronics, conversion algorithms, mechanical housing, and casing). We look to the Guide to the Expression of Uncertainty in Measurements (GUM) to help clarify the terms. The following interpretations are an attempt to clarify terms and help the users understand what is important for their particular use case.

Accuracy

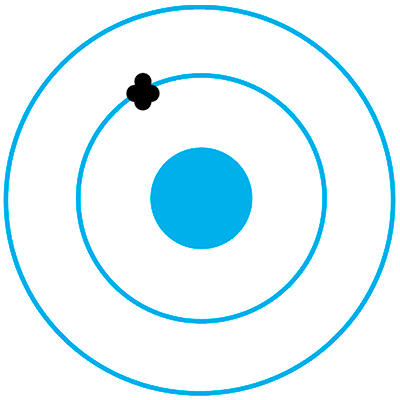

The term accuracy gets thrown around a lot, however accuracy is not typically what we should be concerned with. Accuracy refers to the instrument’s ability to measure the tilt angle compared to the true value. When referring to a string of in-place inclinometers for example, this relates to the measurement of the shape of the casing (i.e. deviation from vertical in the A and B directions), something that is rarely of concern where measuring movement is the key output parameter.

Precision

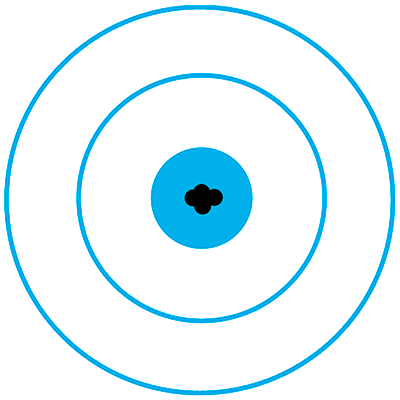

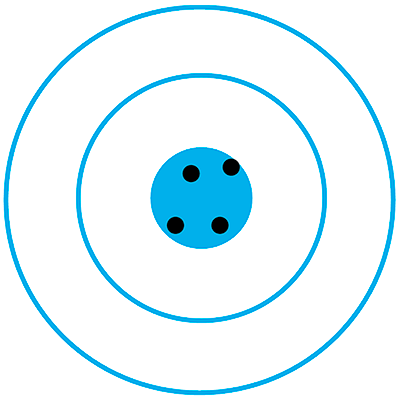

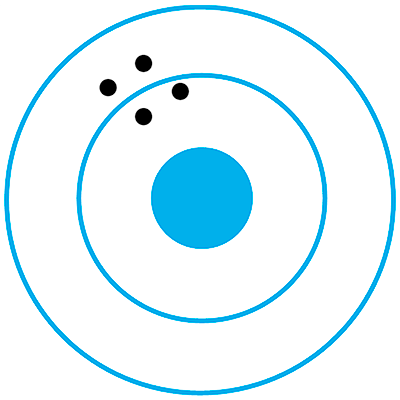

Geotechnical engineers are more concerned with the change in tilt from an original position (i.e. movement), which relates to the precision of the instrument. Precision quantifies the ability of a typical sensor to produce the same reading over and over, and should be qualified by a confidence interval (e.g. 99% confidence). Smaller values of precision are better because they represent the “cloud” of uncertainty around changes in tilt.

Accurate and precise

Accurate, not precise

Precise, not accurate

Not accurate, nor precise

Resolution

The term resolution describes the smallest change in tilt that a sensor can measure, however a sensor with high resolution is of little value if the precision is lower. Example: A specification states a resolution of 0.01 mm, but the precision is 1.0 mm. This instrument will give data that varies widely from reading to reading as changes as small as 0.01 mm can be detected. This could be incorrectly interpreted as movement, however until the sensor shows movement beyond the specified precision of 1.0 mm, we are simply looking at sensor noise.

Repeatability

Repeatability is the ability of a single sensor to produce uniform data over and over under the same conditions.

Stability

This is not a term used by GUM however it refers to a sensor’s repeatability over a defined period of time.

Sensitivity

This is not a term used by GUM however it seems to be used interchangeably with resolution.

Non-linearity

Non-linearity is used to describe the distortion of the measured tilt angle to the true tilt angle across a specified range). It is often stated in lieu of accuracy because it is the predominant factor that limits potential accuracy (i.e. the accuracy of a MEMS sensor varies with the angle being measured.

Temperature Dependent Uncertainty

Temperature changes have a significant impact on tilt readings from MEMS sensors. The impacts are typically reduced by some degree through calibration techniques, however the impacts are hysteretic, meaning that if the temperature goes from 10° C to 20° C or 30° C to 20° C, the measured tilt reading will be different, even though the temperature is the same (20° C). Due to this hysteretic behavior, even with complex calibration processes there is some residual temperature dependent uncertainty.