The inclinometer probe is a totally sealed unit and, as such, field adjustments are not required.

Maintenance of the "O" ring on the connector requires that it be kept clean, as well as free of cuts and nicks. Periodic greasing with "O" lube is recommended. A worn or damaged "O" ring should be replaced with a new one (five "O" rings are supplied with each new probe).

Wheel assemblies should be kept dry when in storage. They should be kept free of dirt by using a compressed air gun to blow away grit. After every survey, spray the springs, pivots and axles with light oil. This is very important and should not be neglected.

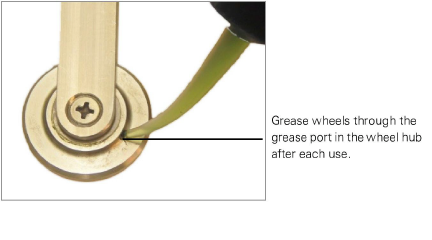

geokon recommends lubricating the wheel bearings after each use with waterproof grease as shown below. This practice forces out any water or contaminates that may be present thus extending the service life.

Figure 114: Wheel Lubricant (ADH-106 Belray Waterproof Grease Type 99540)

Figure 115: Greasing Wheels

One of the main problems encountered is failure to keep the cable and probe connectors dry. Often this is caused by failure to fully tighten the cable connector to the probe connector. This connection must be made up tight in order to compress the O-ring in the end of the probe connector.

Caution: To avoid corrosion, spray the pins of the probe connector periodically with DEOXIT #DN5 spray contact cleaner and rejuvenator. Each inclinometer probe is shipped with a container of this spray. After each daily use, always make sure that the connectors are completely dry before replacing the protective caps.

If the zero shift changes due to aging or rough handling this will not affect the quality or accuracy of the readings because the shift is removed by taking two sets of readings in the A+ and A- directions. However, if the zero shift changes by more than 5000 digits then the probe should be returned to the factory for repairs. Zero shift can be set to zero at any time using the software inside the GK-604 readout instrument (see Section 5.2).

It is good practice to have a piece of inclinometer casing permanently fastened to a fixed immovable structure in the laboratory. This casing is used as a periodic check on the calibration of the probe. Placing the probe in the casing should give a reading that does not change with time.

Remember, from time to time, to backup and remove the survey data from the Field PC. Failure to do this can cause the physical memory to run out and corrupt the system.