Loading... Please wait...

Loading... Please wait...-

Products

- Piezometers

- Inclinometers

- Strain Gauges

- Data Loggers

- Displacement Transducers

- Extensometers

- Settlement Sensors

- Pressure Cells

- Load Cells

- Tiltmeters · Pendulums

- Readouts

- Visualization Software

- Stressmeters

- Distributed Fiber Optic Sensors

- Temperature

- Instrumentation Cables

- DeAerators

- Vibration Monitoring

- Custom Instrumentation

- Discontinued

- Support

- Training

- Contact Us

- News

- Company

- Projects

- Resources

- Videos

- Links

Resources

Session 03

Geotechnical Instrumentation Data Analysis Tips and Tricks

(Part 1 • Data Management)

Posted November 18, 2021

Geotechnical instrumentation data analysis starts with good planning.

Define the geotechnical questions that need to be answered:

- Every instrument on a project should be selected and placed to assist in answering a specific question: If there is no question, there should be no instrumentation—Ralph Peck

Define the purpose of the instrumentation:

- Instrumentation should not be used unless there is a valid reason that can be defended—John Dunnicliff

To set up an instrumentation and monitoring program for success, start with defining the data management requirements for the project

Data Management

- Identify the parties involved and the needs of each party

- Define what success looks like before the project starts

- Select a data management system that is appropriate for your organization/project

- Conduct system validation testing (small scale pilot program)

- Management of factory calibration “sheets”

- procedure for updating calibrations

- Procedure for data screening

- Procedure for setting appropriate collection frequencies | reviewing schedules

- Data calculation instructions (with example)

- Procedure for plotting data (with example)

- Procedure for reporting data to Engineer of Record, owner, or stakeholder

- Automated systems shall include backups | data access | data security

Once the data management requirements are set, determine how data will be collected from each instrument on the project.

Data Collection

- Collection of instrumentation data

- Follow manufacturer’s recommendations

- Documented procedure for data collection

- Maintain field data records

- Personnel qualifications and responsibilities

- Training | Refresher Courses

- The role of automated data acquisition systems

- No automatic system can replace engineering judgement

- Role is to reduce non-value-added work

- Formal initial readings (on site zero reading at thermal equilibrium)

- Field calibration for nontraditional sensors

- High frequency readings until sensor/conditions are stable

- Lower frequency readings for monitoring

- Take readings at the rate at which site conditions are changing

- Consider construction activity

- Consider requirements of data transmission, processing, and interpretation

- Collection of unnecessary data should be avoided

- allowing attention to be focused on the critical parameters to be monitored which can provide early indication of a developing problem

- Subsets of instruments can be assigned for real-time monitoring

- to track the vital signs of the structure as a primary detection network and less frequent readings for designated secondary instruments

Now that the raw data is collected and managed in a systematic way, set the procedure for converted the raw data into engineering units that can be used to make quick, informed decision.

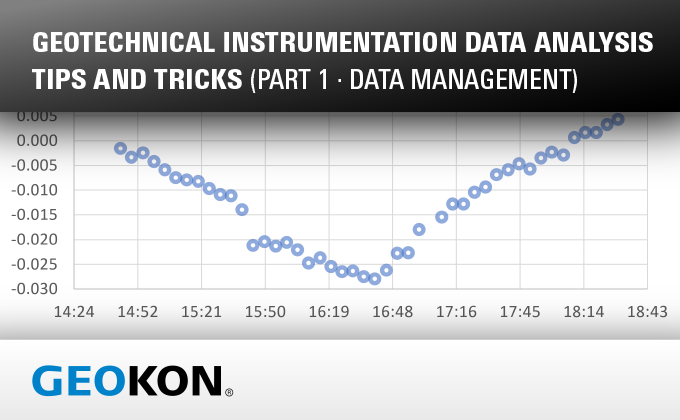

Data Processing

- Provide rapid assessment to detect changes requiring action

- Summarize and present data to:

- show trends

- compare observed with predicted behavior

- Should be automated wherever possible

- Raw data should always be retained

- Automated data conversions should be validated by a qualified person

- Personnel qualifications

- requires significant judgement

- do not delegate to inexperienced personnel