Loading... Please wait...

Loading... Please wait...-

Products

- Piezometers

- Inclinometers

- Strain Gauges

- Data Loggers

- Time Domain Reflectometry (TDR)

- Displacement Transducers

- Extensometers

- Settlement Sensors

- Pressure Cells

- Load Cells

- Tiltmeters · Pendulums

- Readouts

- Visualization Software

- Stressmeters

- Distributed Fiber Optic Sensors

- Temperature

- Instrumentation Cables

- DeAerators

- Vibration Monitoring

- Custom Instrumentation

- Discontinued

- Support

- Training

- Contact Us

- News

- Company

- Projects

- Resources

- Videos

- Links

Resources

Session 04

Geotechnical Instrumentation Data Analysis Tips and Tricks

(Part 2 • Data Presentation, Interpretation and Reporting)

Posted November 24, 2021

Every good monitoring program consists of clear presentation of instrumentation data alongside other site metrics to present a cause-and-effect picture of how the site is performing.

The following are some tips to ensure that instrumentation data is presented in the most clear and concise manner.

Data Presentation

- Plots to assist data screening

- lines of best fit to smooth out data (remove outliers)

- Plot data vs time for full data set

- to assess data quality and show trends

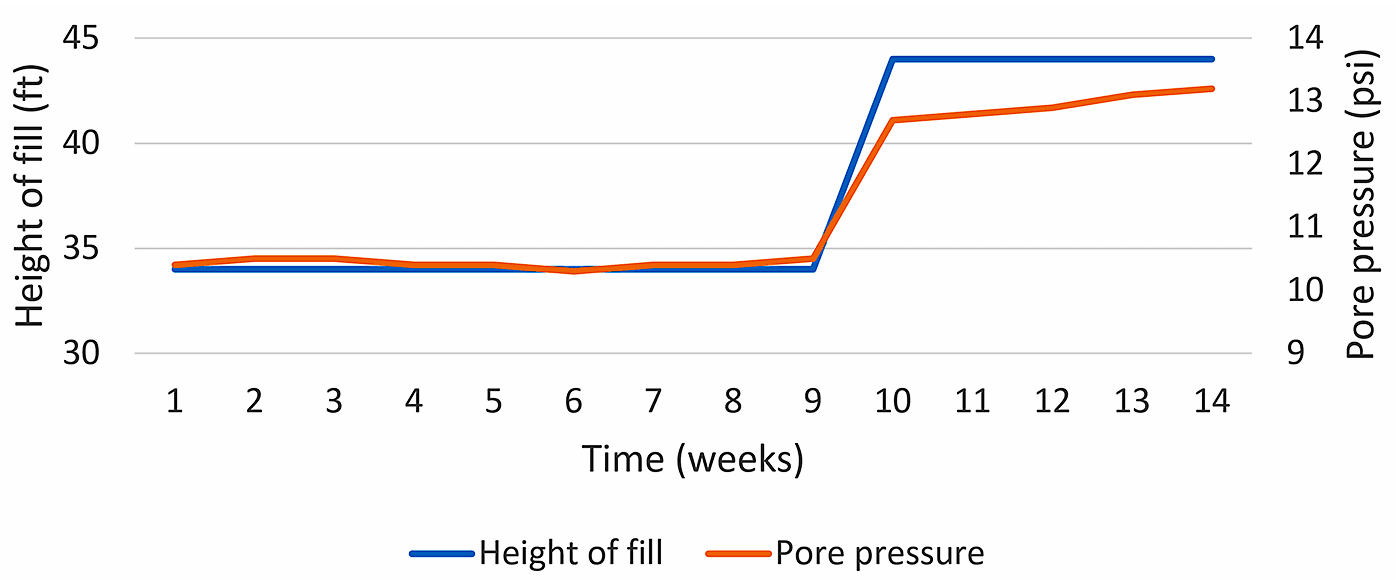

- Plots showing observed vs predicted behavior

- plotted regarding time and on same axis

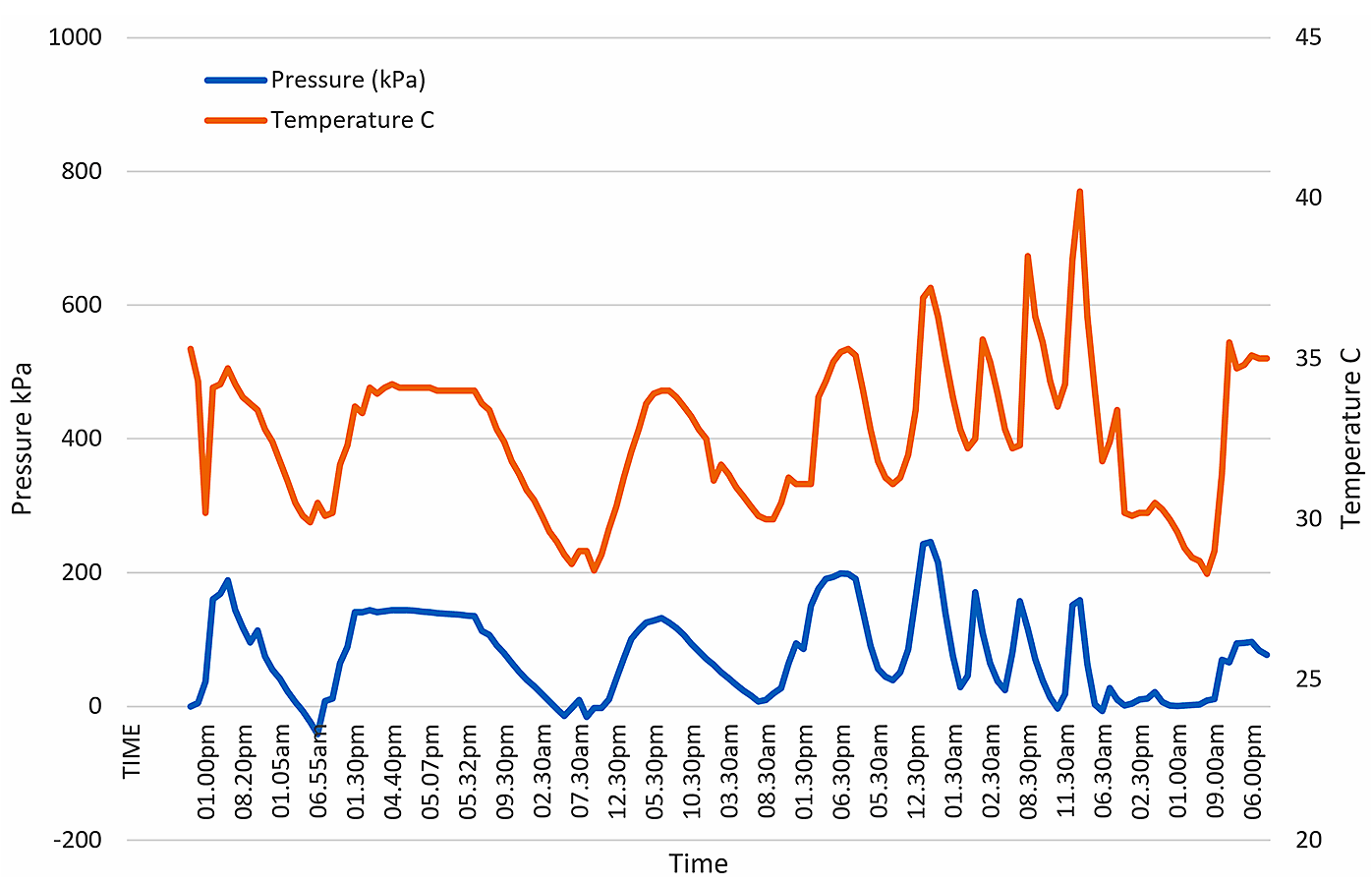

- Plots comparing measurements and observations

- often form part of data interpretation

- plotted regarding time and on same axis

- e.g., fill placement, pond level, rainfall, and pore water pressure

- Plots to examine cause and effect relationships

- e.g., pore pressure increase and settlement as a function of fill placement

- Determine the magnitude of change in the monitoring parameters required to validate performance of the structure

- and verify that the proposed instruments can detect that magnitude of change

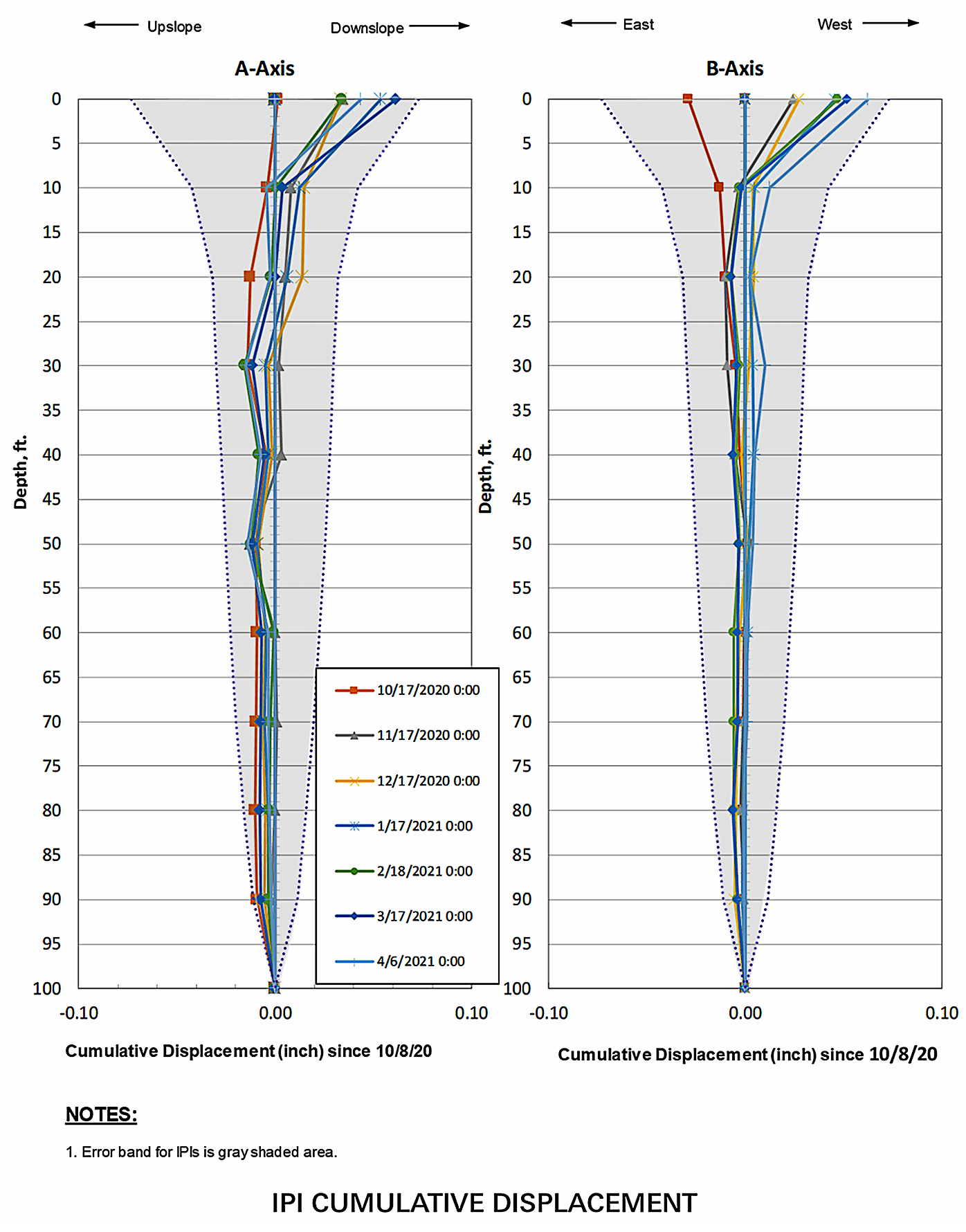

- Plot error bands on all data sets to assist in interpreting actual change in conditions vs possible sensor errors

- Can the instruments you selected be sampled by the proposed system at the frequency required by your monitoring plan?

Data Interpretation

- Qualified personnel

- Follow a pre-determined procedure

- Do not delay interpretation

- data collection, processing and interpretation influence each other

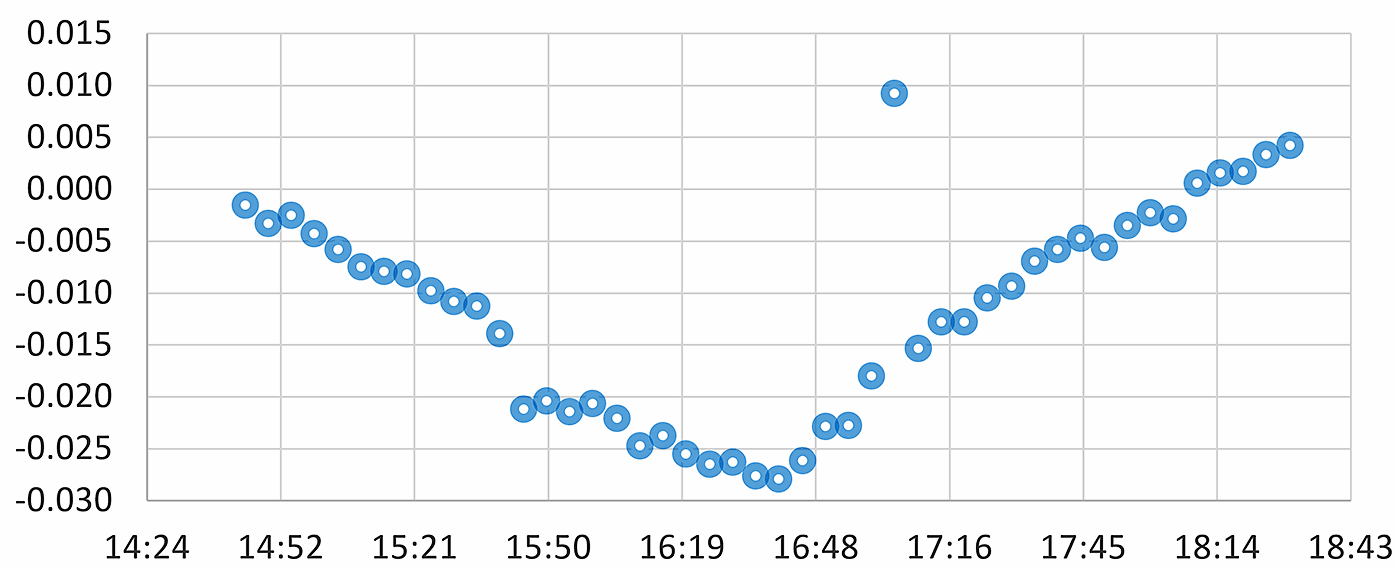

- Create plots with meaningful interpretation in mind

- e.g., units from a MEMS IPI sensor can be displayed in:

- Raw data digits

- Acceleration in g

- Tilt in radians

- Tilt in degrees

- Displacement in mm/m or in/ft

- e.g., units from a MEMS IPI sensor can be displayed in:

- First reaction is to reject unanticipated readings and/or blame the sensor, but data may be real (and be important)

- Consult with manufacturer to better understand performance of the instrument in question

- Ask “Can I think of a hypothesis that is consistent with the data”

- check reading correctness to assess data validity

- zero readings, gage factors, temperature corrections, barometric pressure, datalogger programs/power

- check raw data

- check installation records | difficulties encountered during install

- site and environmental conditions

- Construction, rainfall, headpond level

- check reading correctness to assess data validity

Compare Instrumentation data with design models

- Before reviewing data get a feel for what the values should be based on the design model and existing conditions

- How sensitive are model results to input parameters (parametric studies should be undertaken to show a range of expected results based on variation in soil type, water level, temperature etc.)

- Are there any localized conditions that could result in variations from the modelled section?

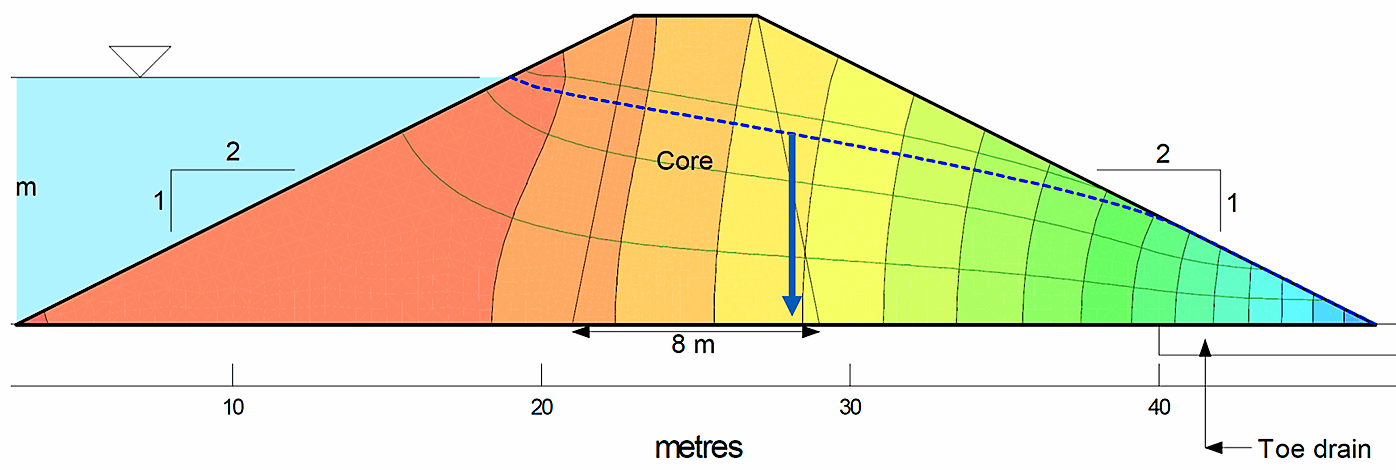

VW Piezometer installation location and predicted water level | Reference: www.geostudio.com

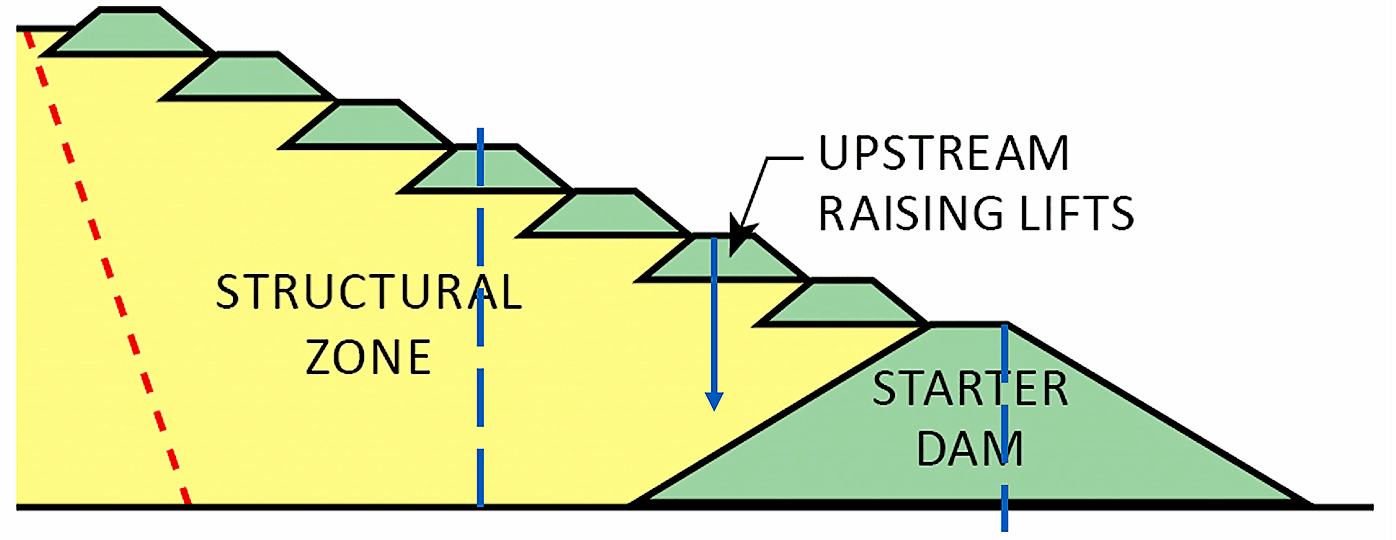

Screen the data for expected site conditions vs. actual site conditions

- Before reviewing instrumentation data make sure the site conditions and change in those conditions with time is understood

- Construction data is often not synced to instrumentation data making it difficult to determine the loads the instruments are subjected to at the time of the readings

- There can be disconnects between the engineer(s) reviewing the instrumentation data and the designer/construction inspector

Reference: www.klohn.com/blog/best-practices-for-tailings-dam-design

Reporting

- Conclusions, drawn from interpretations must be:

- Reported and submitted

- to those responsible for implementation of data on a regular schedule

- Reported and submitted

- Final report to include

- introduction, why are we monitoring

- any design and construction information relative to monitoring program

- summary of monitoring program plan

- description of instruments and readouts and calibration procedures

- plans and sections

- surface and subsurface geotechnical data

- procedures for data collection, processing, presentation, and interpretation

- observed behavior with measured data and influencing factors and predicted behavior

- conclusions, discussion, and remedial action

- assessment of monitoring program along with suggested improvements